Cad Modelling Services

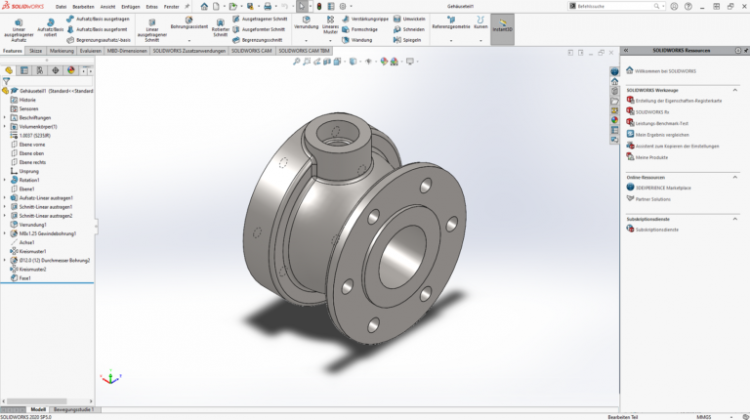

3D modeling or CAD (Computer-Aided Design) allows engineers and designers to build realistic computer models of parts and assemblies. These models can be then 3D Printed or CNC machined as well as used to run complex simulations. A wide range of parameters can be simulated such as strength or temperature resistance before any physical models have been created, enabling a much faster and cheaper workflow.

Solid modeling creates solid 3d models as if they are actual parts, with a logical workflow that is similar to the processes which would be used to manufacture the part. Some of these operations include extruding, drilling and threading operations. Solid models can intersect, join and subtract objects from one another to create the desired part.

Another advantage of solid modeling is that it is usually parametric, meaning that changes or parameters are saved at every stage of the modeling process and can be edited at any time during the design. This is very useful as it allows features of the model to be quickly modified without needing to create the part from scratch.

Assembly modeling is also an important stage in solid modeling, allowing individual parts to be assembled together, forming complex models. Assemblies can be used to insert standard components such as fasteners or bearings, that have been downloaded directly from the manufacturers. Motion elements can also be applied to assemblies, allowing detailed motion analysis to be used to evaluate the mechanical performance of the design.

Surface modeling is usually used for more aesthetic features of a product. It is much easier to create more organic and free-form geometry using this type of CAD software. Many of the constraints found in solid modeling are not an issue with surface modeling, however, this comes at a cost of sometimes being less accurate.

As the name suggests surface modeling only contains surfaces of the part, with no solid interior. However, once the part has enough surfaces to close the part, it can be filled and then used for 3D printing. When developing designs using surface modeling, it can be hard to go back and make changes because usually, it is not parametric.

Each type of modeling software has benefits and drawbacks, depending on the type of design being produced this needs to be considered. Sometimes using both solid and surface modeling is needed to combine the benefits of each.