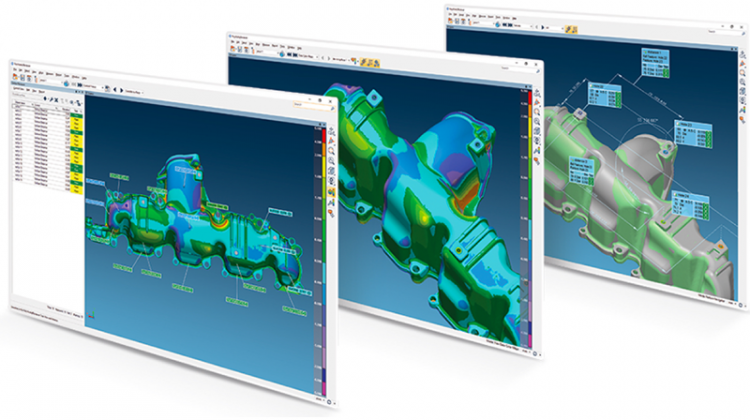

Dimensional Inspection Services

Dimensional inspection is sometimes referred to as dimensional measurement or dimensional metrology and is a specialized field encompassing a broad range of applications from large, complicated parts such as jet engine turbines to extremely small parts with tight tolerances that are part of life-saving medical devices. In manufacturing, this object might be a prototype for R&D or a custom-made component for a new production line or even a finished product. Simplified, dimensional inspection can be seen as the process for comparing what an object actually is to what it is supposed to be, and uses quantifiable values to measure virtually any physical characteristics such as:

- Length, width, and height.

- Angles and perpendicularity.

- Roundness, flatness, and other geometric characteristics.

- Position.

- Shape profiles.

- Surface characteristics.

- Edge sharpness.

- Thickness and uniformity.

It’s critical to have viable and reliable means of accurately verifying your manufactured products and manufacturing processes. One of the primary ways to accomplish this is via an in-depth evaluation of the first piece from your production run — also called first article inspection. We take great care in comparing the actual condition of manufactured parts, components, tooling and dies to the nominal condition as expressed in 2D drawings, 3D Models,